DESIGN SERVICE

CERATE YOUR OWN SYSTEM & SOLUTION

CONSULTING SERVICE

CONSULTING SERVICE

We provide comprehensive consulting services tailored to your specific application requirements. By evaluating factors such as sample material, dimensions, and structural characteristics, we develop optimal strategies for image acquisition and processing. Our expertise encompasses the selection of critical components, software functionality, and process design, enabling us to deliver fully customized X-ray imaging inspection solutions that meet the highest standards of precision and efficiency.

CUSTOMIZED SYSTEM DESIGN

CUSTOMIZED SYSTEM DESIGN

With years of experience in system design, we specialize in developing advanced solutions such as high-speed inline scanning systems and CT equipment. Our services include the integration of critical components, seamlessly combined with our proprietary imaging platform, PortalX, and reconstruction software, ReconX. We also offer customized image processing capabilities to deliver comprehensive solutions tailored to your specific inspection requirements.

KEY BENEFITS

KEY BENEFITS

Expert team in mechanics, electronics, software, and image processing

Proven success in CT system design and manufacturing

In-house developed control platform : PortalX

Robust 3D reconstruction software : ReconX

Experience in production line and central system integration

End-to-end support for product evaluation and development

CASE SHARING

PARTIAL-ANGLE VERTICAL CT

High-speed inspection systems designed for the semiconductor, PCB, and display panel industries, enabling 3D imaging of specific-height structures within flat materials.

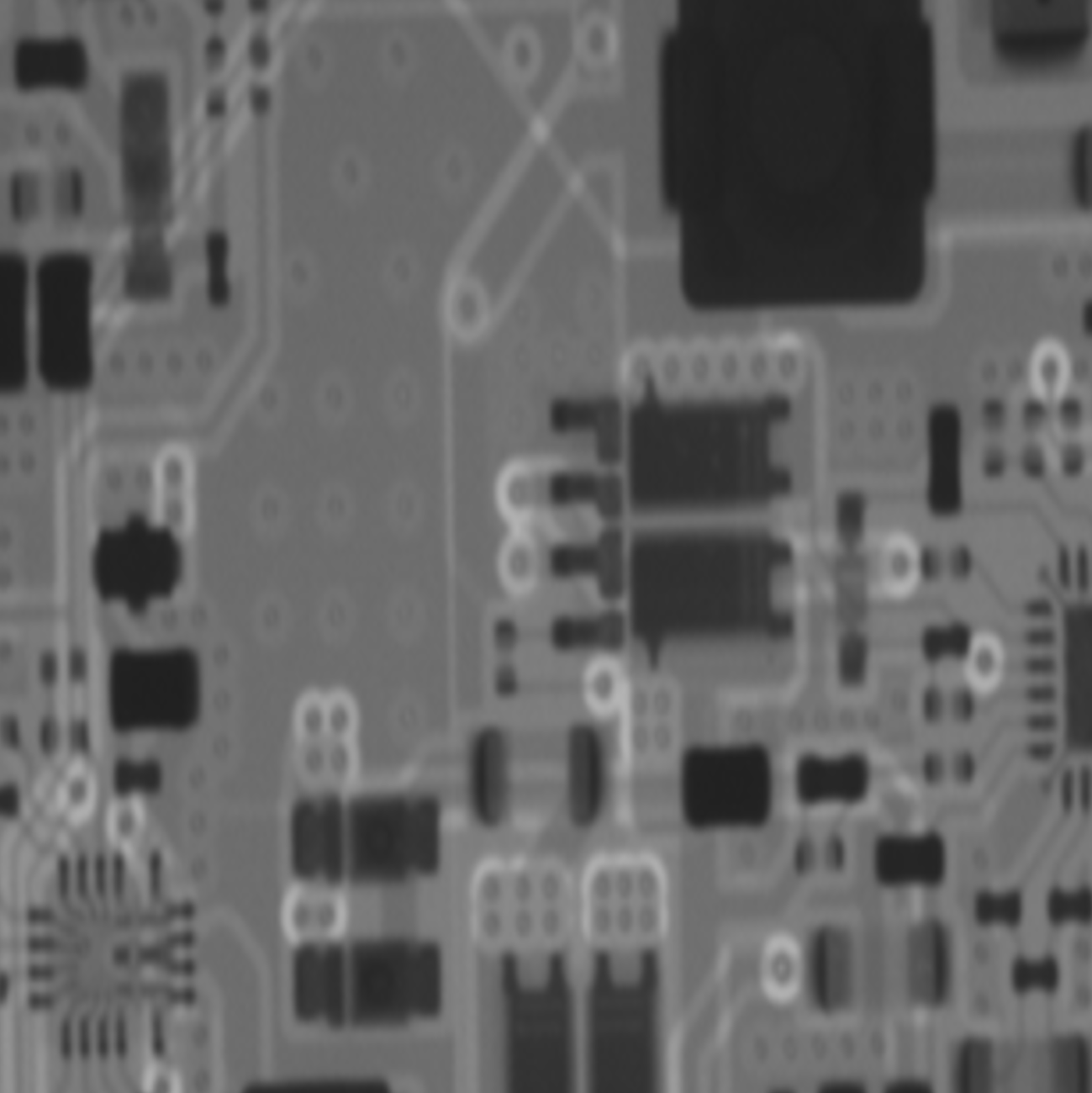

LABORATORY MICRO CT

Designed with high resolution and high magnification capabilities, ideal for failure analysis, material identification, and internal structure inspection.

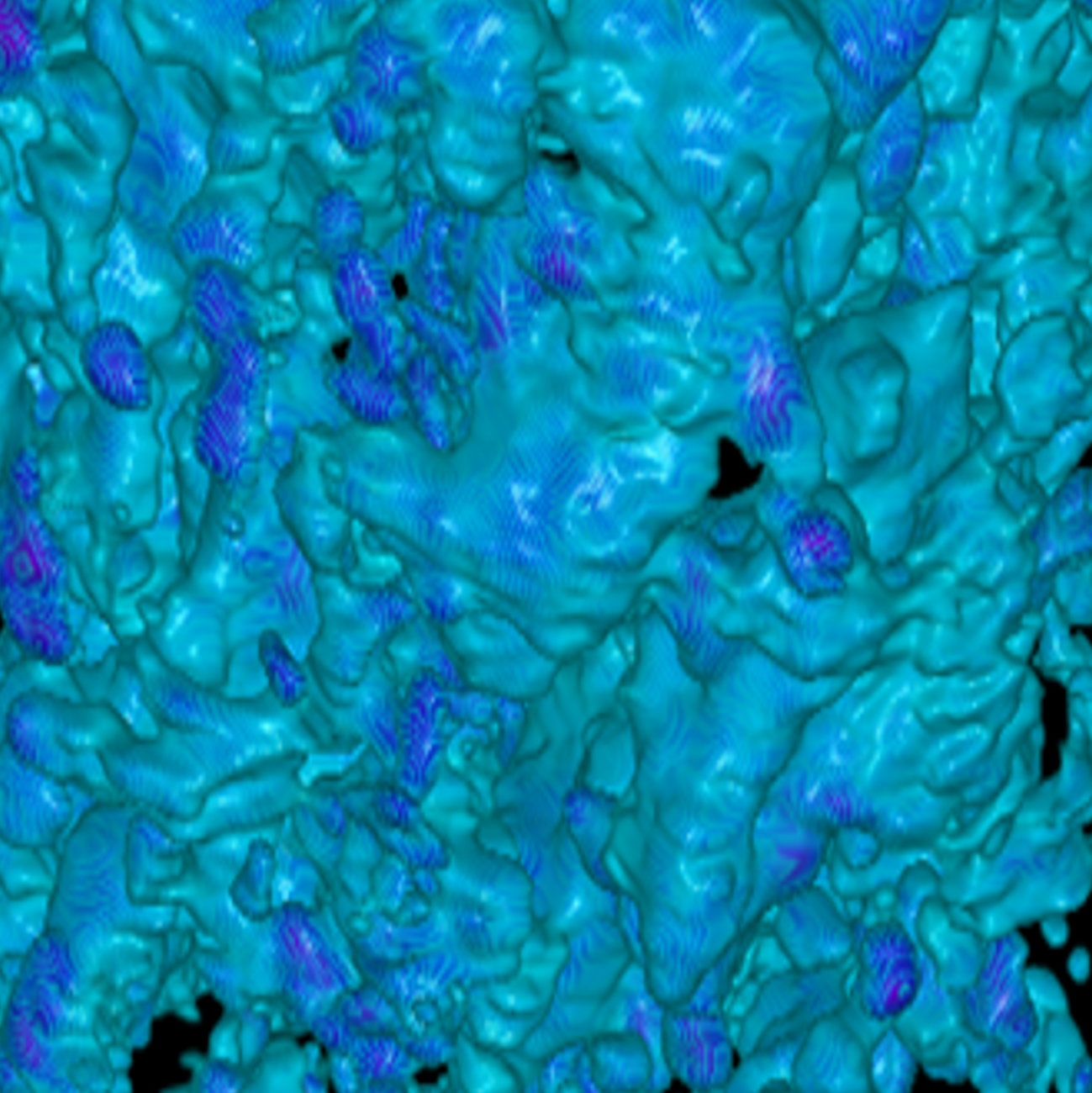

GOLF INLINE INSPECTOR

For inline quality control, the system enables rapid detection of internal defects and dimensional measurement of spherical components, facilitating real-time sorting and statistical analysis on the production line.

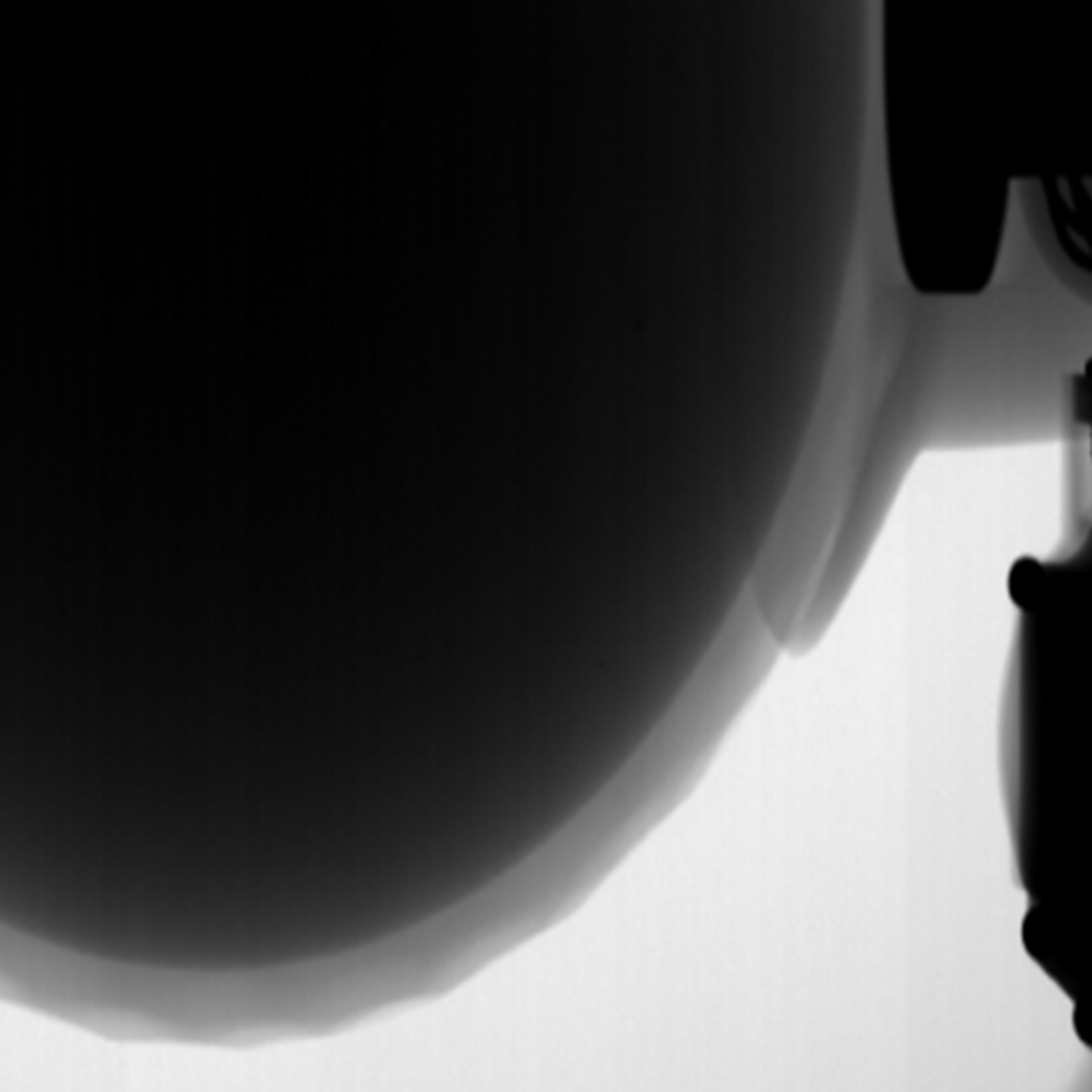

HAND-BONE DENSITOMETRY

Enables low-dose, high-resolution hand imaging for subjects, with AI-powered analysis to assess bone age, bone density, and growth curve positioning.

成功案例

PARTIAL-ANGLE VERTICAL CT

High-speed inspection systems designed for the semiconductor, PCB, and display panel industries, enabling 3D imaging of specific-height structures within flat materials.

LABORATORY MICRO CT

Designed with high resolution and high magnification capabilities, ideal for failure analysis, material identification, and internal structure inspection.

GOLF INLINE INSPECTOR

For inline quality control, the system enables rapid detection of internal defects and dimensional measurement of spherical components, facilitating real-time sorting and statistical analysis on the production line.

HAND-BONE DENSITOMETRY

Enables low-dose, high-resolution hand imaging for subjects, with AI-powered analysis to assess bone age, bone density, and growth curve positioning.